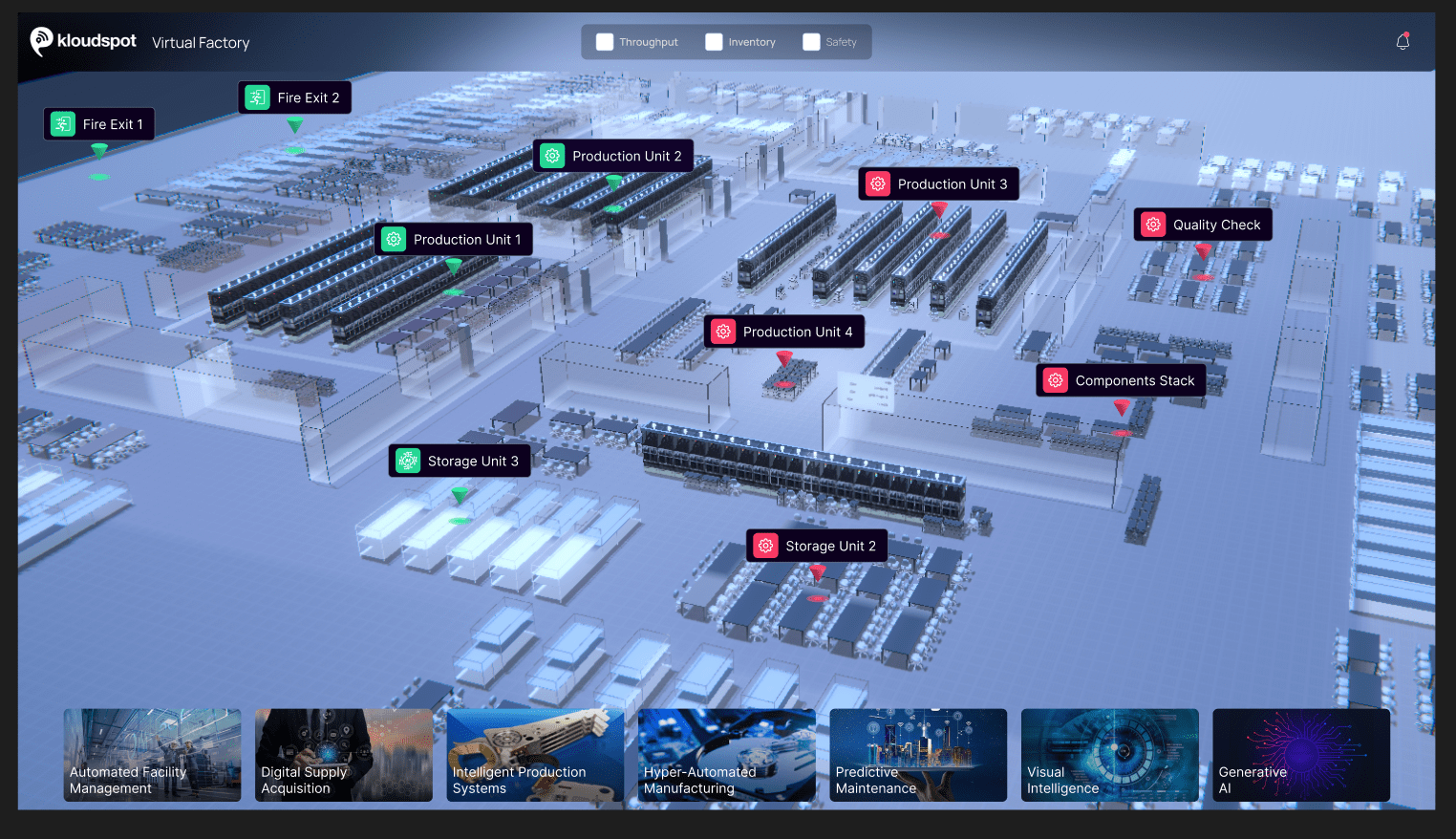

The manufacturing industry is at a pivotal moment. As Industry 4.0 continues to redefine traditional processes, manufacturers are increasingly turning to digital twins—virtual replicas of physical systems — to optimize operations and unlock new efficiencies. While digital twins promise transformative potential, they also present challenges, particularly in terms of data integration and practical implementation.

Enter Kloudspot. By redefining how digital twins are designed and utilized, Kloudspot’s solutions are reshaping manufacturing. From boosting yield to enhancing machine uptime and ensuring safety, Kloudspot’s innovative approach is setting a new benchmark for smart factories.

At its core, Kloudspot’s value proposition in manufacturing revolves around three primary areas:

Yield Optimization: Manufacturing facilities constantly seek to maximize output while minimizing waste. Kloudspot’s digital twins analyze process inefficiencies and provide actionable insights, helping manufacturers enhance production yield.

Machine Uptime: Downtime is the enemy of profitability. With predictive maintenance capabilities and real-time monitoring, Kloudspot ensures that machines run smoothly, reducing unplanned downtime and extending equipment lifespan.

Safety Enhancements: Worker safety remains paramount in manufacturing. Kloudspot’s solutions identify potential hazards, monitor compliance, and provide actionable insights to ensure a safer working environment.

The Power of Data Fusion

One of Kloudspot’s most compelling differentiators is its ability to fuse diverse data sources: controls data, sensor data, and video streams into a single digital twin. Most manufacturers are on a journey to collect and monetize data. However, the inability to view controls, sensors, and video data in one place often limits the value derived from these efforts. Kloudspot’s approach ensures all data sources coexist in a unified digital twin, providing a holistic view of operations.

Consider a factory where machinery performance is monitored through sensors, and worker behavior is captured on video. Separately, these data sources provide limited insights. Together, they can detect unsafe practices and trigger alerts, correlate machine vibrations with operator actions to diagnose root causes of faults, and provide a 360-degree view of operations for better decision-making.

Historically, manufacturers have relied on expensive pilots to develop custom digital twin solutions. These efforts often fail to scale due to high costs and limited business cases. Kloudspot addresses this challenge with pre-built models and capabilities. Kloudspot’s out-of-the-box solutions offer a strong starting point for manufacturers. Whether it’s predictive maintenance, yield optimization, or safety improvements, these models deliver immediate value.

Use Cases

Predictive Maintenance: This involves using digital twins to monitor equipment performance in real time and predict when maintenance is required. By analyzing data trends from sensors and machine logs, manufacturers can schedule maintenance before failures occur, reducing downtime and associated costs.

Yield Optimization: Digital twins analyze production processes to identify inefficiencies. By simulating different scenarios and adjustments, manufacturers can optimize settings, minimize waste, and increase overall production output.

Plant Safety: Kloudspot’s solutions use video and sensor data to detect unsafe working conditions, such as the presence of unauthorized personnel or hazardous materials. Plants can also set their own PPE policies, with real-time, vision-based enforcement augmenting the effort of safety monitoring personnel. Real-time alerts ensure that safety standards are upheld, reducing workplace incidents.

Production Line Optimization: Combining data from sensors and video feeds, digital twins provide insights into the synchronization of equipment and personnel. This ensures that all elements of the production line work in harmony for maximum efficiency.

Defect Detection: By integrating video analytics, digital twins identify defects in products as they are manufactured. This allows for immediate corrective action, reducing waste and ensuring quality control.

Energy Management: Kloudspot’s solutions monitor energy usage across a facility. Inefficiencies and opportunities for improvement, such as identifying the optimal time to start a machine or avoiding demand charges when possible, help reduce spend and further ESG goals.

Inventory Tracking: By combining RFID data with digital twin models, manufacturers gain better visibility into inventory levels.This reduces overstocking or stockouts and minimizes waste from expired or unused materials. Additionally, Kloudspot can simulate the impact of suboptimal inventory levels on future production.

Workflow Automation: Digital twins analyze real-time data to identify bottlenecks in workflows. Insights enable automation and process adjustments, streamlining operations and boosting productivity.

Training and Simulation: Virtual replicas of manufacturing environments allow employees to train in realistic scenarios without disrupting actual operations. This enhances skill development and prepares workers for complex tasks or emergencies.

Disaster Recovery Planning: Digital twins simulate potential risks like equipment failures or natural disasters. By testing different contingency plans, manufacturers can minimize downtime and losses during actual emergencies.

Unlike traditional integrators, Kloudspot’s approach is deeply rooted in operational technology (OT). By incorporating feedback from OT teams into twin design and model training, Kloudspot ensures its solutions are practical and relevant. Traditional IT-driven approaches to digital twins often lack the granular insights required by OT teams.

Kloudspot bridges this gap, ensuring seamless collaboration between IT and OT stakeholders. By integrating OT feedback, Kloudspot’s digital twins are better equipped to address real-world manufacturing challenges, making them more reliable and effective. While most technology solutions favor cloud-based architectures, Kloudspot recognizes the unique needs of manufacturers and offers robust on-premise solutions.

Manufacturing facilities handle sensitive data, from proprietary processes to machine controls. Ensuring deployment flexibility is key, whether manufacturers want to benefit from the scale and power of a cloud-based deployment or they opt for an on-prem solution that limits their security exposure and optimizes latency. Manufacturing processes operate in microsecond timeframes, where delays can have significant consequences.

Kloudspot’s on-premise solutions provide real-time responses, ensuring seamless operations. Sending large data streams like video or vibration analytics to the cloud can strain networks. Kloudspot’s on-premise approach alleviates these challenges, ensuring uninterrupted data processing.

Kloudspot’s digital twin solutions are already making waves in the manufacturing sector:

Automotive Manufacturing: Automotive assembly lines involve complex machinery and precise coordination. By integrating video feeds and sensor data, Kloudspot optimizes assembly line performance. For example, it can identify bottlenecks, reduce defect rates by spotting anomalies in real-time, and enhance synchronization across the production process. This approach ensures higher efficiency, improved quality, and reduced downtime.

Chemical Plants: Chemical manufacturing involves high-stakes processes where equipment failure can lead to significant financial and safety risks. Kloudspot’s predictive maintenance models analyze data from sensors monitoring pressure, temperature, and vibration to predict potential failures. By addressing issues proactively, plants minimize unplanned shutdowns, saving millions in potential losses while ensuring workplace safety.

Electronics Manufacturing: In electronics production, ensuring workplace safety is critical, as employees handle delicate components and hazardous materials. Kloudspot uses real-time video and sensor monitoring to identify unsafe practices, detect spills or hazards, and ensure compliance with safety protocols. This reduces workplace incidents and fosters a safer working environment, all while maintaining productivity.

Food and Beverage Industry: The food and beverage sector demands strict quality control and process tracking. Kloudspot’s data fusion combines sensor data with video analytics to monitor the production process closely. For example, it ensures ingredients are mixed at the correct temperatures and proportions, tracks production speed, and identifies potential contamination risks. This leads to better product quality, less waste, and adherence to regulatory standards.

Pharmaceutical Manufacturing: Pharmaceutical production is subject to stringent regulatory requirements. Kloudspot’s digital twins monitor production processes in real time, ensuring compliance with these regulations. Video analytics track critical procedures like packaging, while sensor data ensures temperature and humidity are maintained at required levels. Automated reporting simplifies audits and reduces human error, helping pharmaceutical companies maintain compliance and improve operational transparency.

The Future of Manufacturing

As Industry 4.0 evolves, digital twins will play an increasingly vital role in manufacturing. Kloudspot is at the forefront of this revolution, continuously innovating to address emerging challenges and opportunities like:

AI and Machine Learning: Leveraging advanced algorithms to enhance digital twin capabilities.

Sustainability: Using digital twins to reduce energy consumption and minimize waste.

5G Integration: Enabling faster and more reliable data processing for real-time insights.

From integrating new data sources to refining existing models, the company is poised to shape the future of manufacturing. Kloudspot’s digital twin solutions are transforming manufacturing, delivering unparalleled value through yield optimization, machine uptime, and safety enhancements. With unique differentiators like data fusion, out-of-the-box capabilities, OT-friendly design, and on-premise solutions, Kloudspot stands out in the Industry 4.0 landscape. For manufacturers ready to embrace the next frontier of factory optimization, Kloudspot offers the tools and expertise to drive meaningful change. Kloudspot remains committed to pushing the boundaries of digital twin technology.