Operational visibility, predictive maintenance, and process optimization have become non-negotiable for achieving competitive advantage. While many technology providers promise Industry 4.0 transformation, few deliver the integrated, real-time intelligence that modern factories demand.

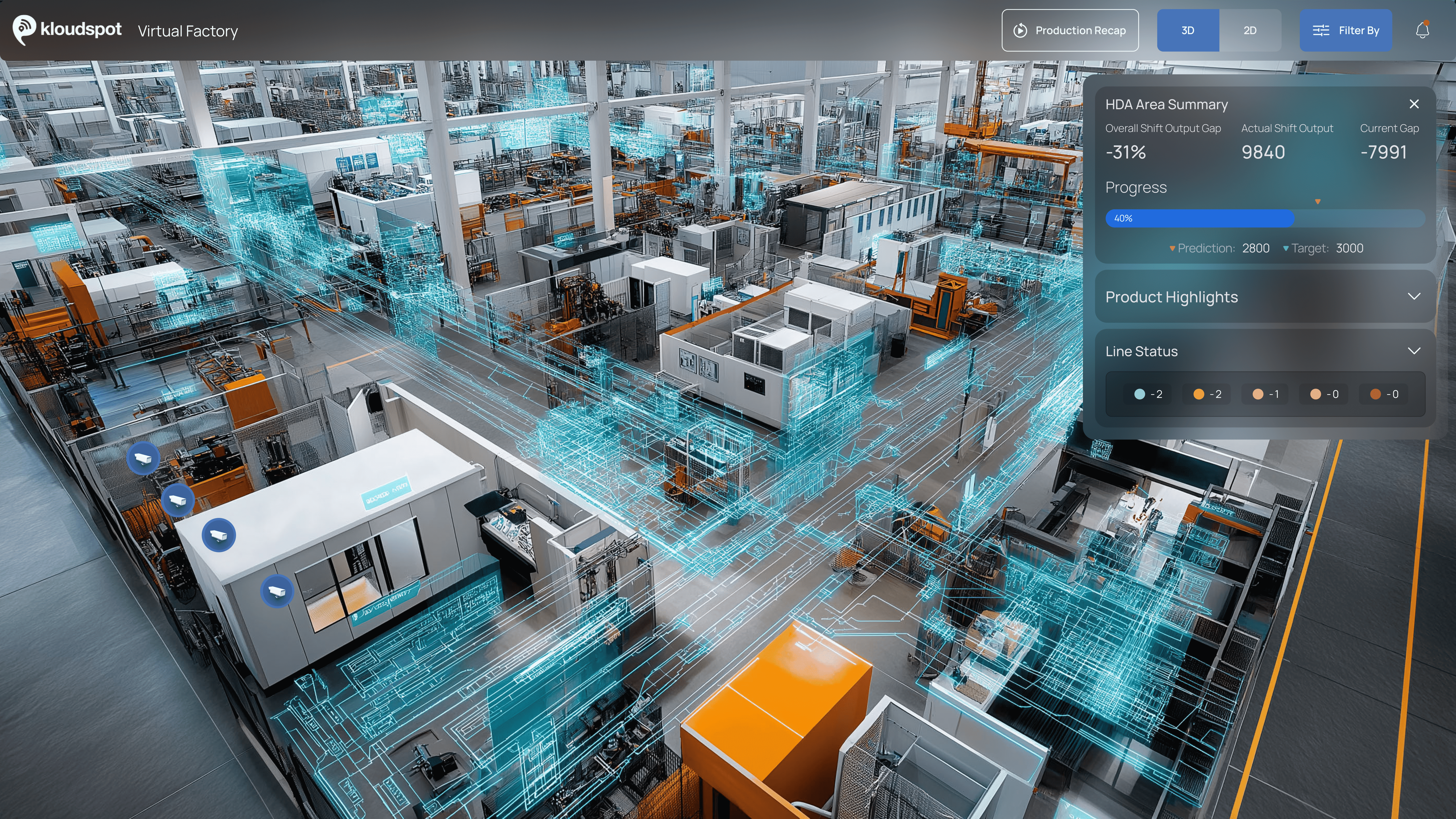

Kloudspot’s LISA platform stands out by redefining manufacturing intelligence through Physical AI. By fusing unparalleled sensor data with AI-driven insights and dynamic digital twins, LISA transforms the physical world into actionable intelligence. This powerful combination not only sets a new industry benchmark that competitors struggle to match but also delivers benefits that are both highly desirable and mission-critical for the success of modern manufacturing operations.

Kloudspot’s Differentiation

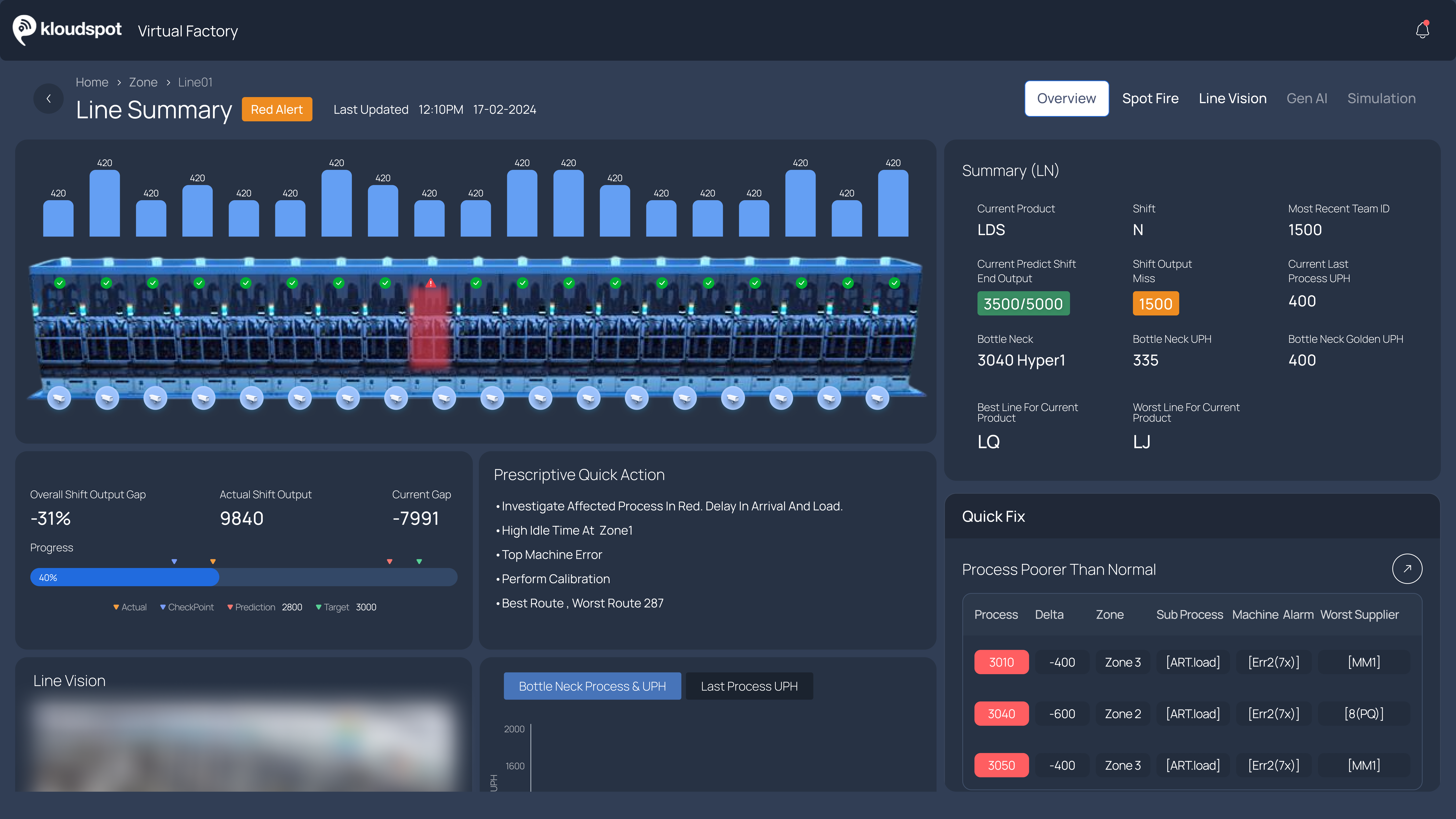

At the heart of Kloudspot’s leadership is its ability to seamlessly integrate diverse data streams, including Wi-Fi and Bluetooth, video analytics, RFID, environmental sensors, and access control systems, into a single, cohesive, and actionable view. Unlike many competitors who rely on siloed data or slow batch processing, Kloudspot’s LISA platform provides continuous, real-time digital twin updates, enabling instantaneous decision-making.

This fusion of multi-modal sensor data empowers manufacturers to:

- Gain granular, floor-level situational awareness accessible in intuitive dashboards

- Anticipate equipment failures with predictive maintenance alerts generated by AI-driven analysis

- Optimize production workflows by simulating “what-if” scenarios directly on digital twins

- Enhance worker safety through automated monitoring and access control

While other physical AI providers offer partial solutions, predominantly focused on robotics or isolated IoT sensors, Kloudspot’s platform is uniquely holistic and scalable, serving diverse manufacturing environments ranging from automotive assembly lines to electronics fabrication floors.

How Kloudspot Elevates Manufacturing Performance

- Operational Visibility: Kloudspot’s real-time fusion of spatial and environmental data allows plant managers to monitor asset utilization and worker movements with unmatched precision. This eliminates blind spots common in systems relying on single data types or periodic reporting.

- Predictive Maintenance Redefined: By correlating sensor inputs with historical performance trends, Kloudspot anticipates maintenance needs well before breakdowns occur, significantly reducing unplanned downtime and associated losses. Competitors often lag due to slower or less comprehensive data analysis capabilities.

- Process Optimization through Digital Twins: Kloudspot enables manufacturers to test production changes digitally before implementing them physically. This capability drives faster innovation cycles and resource savings—a marked advantage over rivals relying on static or delayed datasets.

- Safety and Compliance: By automating environmental and access monitoring, Kloudspot proactively flags potential safety breaches and compliance issues, a critical differentiator in heavily regulated manufacturing sectors.

- AMR Operations Optimized: Kloudspot provides granular, real-time visibility into AMR (Autonomous Mobile Robot) movements, route efficiency, and battery status throughout the factory floor. By continuously analyzing spatial and operational data, plant managers can address inefficiencies and preempt downtime, ensuring AMRs deliver consistent productivity gains.

Why Kloudspot Leads

- Comprehensive Data Integration: No other provider combines as many sensor types into a unified, real-time platform.

- Scalable and Vendor-Agnostic: Kloudspot easily integrates with existing infrastructure and scales across multiple sites without lock-in, unlike many closed or single-vendor ecosystems.

- Privacy-First Edge AI Architecture: Enables data processing near the source, minimizing latency and ensuring compliance with data privacy regulations.

- Proven Industry Impact: Award-winning technology recognized for breakthrough innovation, trusted by leading manufacturers to transform smart factory operations.

As manufacturers accelerate toward Industry 4.0, choosing the right physical AI partner can define success or stagnation. Kloudspot’s LISA platform meets the demands of today’s complex factories and anticipates the needs of tomorrow’s innovative manufacturing ecosystems. For manufacturers seeking operational excellence, safety, and sustainable growth, Kloudspot is a trusted and transformative technology partner.

Contact Kloudspot today for a personalized demo.