In manufacturing, every sensor reading matters. The pursuit of higher yield—extracting maximum output with minimal waste—defines operational excellence. Today’s factories demand more than automation. They require intelligence that anticipates and acts. Kloudspot’s Physical AI‑driven Digital Twin platform empowers plant managers and their teams to achieve this intelligence. By merging real‑time data from machines, material flow, and environmental factors, it transforms raw process information into insights that continuously improve production yield.

From Data Streams to Actionable Insights

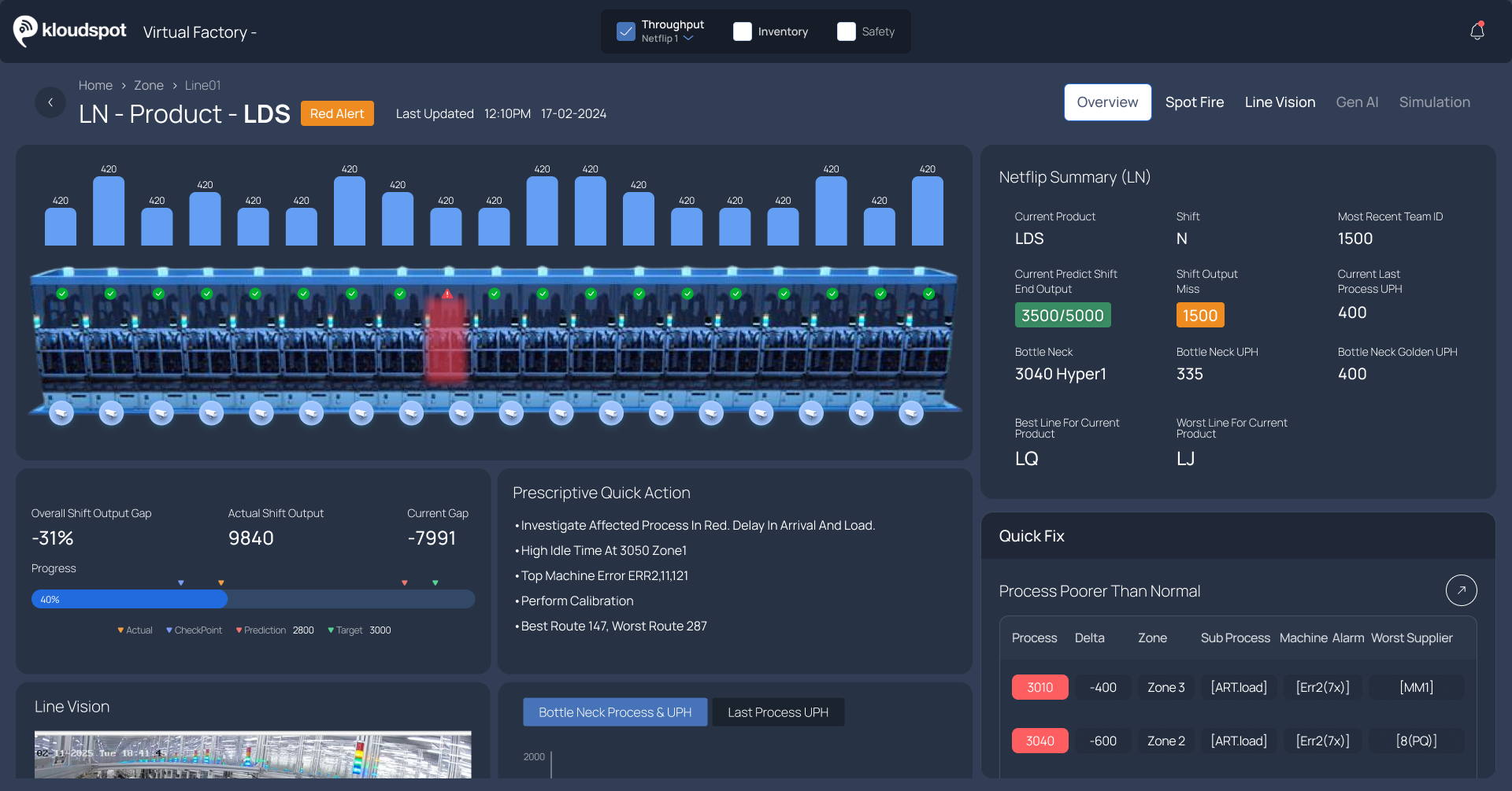

Modern factories are data powerhouses. Sensors track everything from temperature and vibration to torque, voltage, and humidity. Machine logs record production cycles and equipment status, while cameras and IoT devices capture visual cues from assembly lines, conveyors, and packaging zones. Instead of viewing these as isolated streams, Kloudspot’s Digital Twin platform unifies them into a single, interactive model, a living, digital replica of your factory floor. This isn’t a static dashboard. It’s a synchronized, intelligent reflection of fundamental operations that enables managers to see, predict, and dynamically optimize performance.

By continuously analyzing line data, the platform highlights anomalies and inefficiencies:

- Machines performing below their optimal parameters

- Material imbalances are causing micro-bottlenecks

- Hidden cycle delays that gradually erode throughput

Operators no longer need to rely solely on periodic reviews or guesswork. With Physical AI, they gain access to live intelligence, turning every sensor reading into a decision point that drives yield improvement.

Yield Optimization as a Core Value

Yield optimization isn’t just a feature of Kloudspot’s platform. It’s the outcome of its core intelligence. Using AI models trained on both historical patterns and live sensor data, the system simulates and predicts the impact of minute process variations before they occur. Imagine adjusting the feed rate, pressure, or temperature in a critical stage of production. The platform forecasts how that change will affect final output, energy consumption, and waste percentages, and then recommends actions to achieve an optimal balance.

This proactive intelligence enables manufacturers to:

- Fine-tune line efficiency to maintain consistent quality

- Detect early signs of deviation before costly losses occur

- Continuously learn from closed-loop feedback in the digital twin

Over time, this self-reinforcing system becomes a “living process expert,” allowing even complex manufacturing environments to sustain high yield performance with fewer manual interventions.

Predictive Maintenance: Protecting Performance

Production yield depends on materials, processes, and healthy machines. Kloudspot’s Physical AI extends yield optimization into equipment reliability through predictive maintenance. By continuously monitoring parameters such as vibration patterns, temperature deviations, and runtime anomalies, the system detects early signs of fatigue or wear long before traditional inspection schedules would. Maintenance teams receive predictive alerts backed by diagnostic insights, enabling them to act precisely when needed. This results in fewer unplanned downtimes, longer equipment life, and more predictable asset performance, ensuring that the production floor operates at peak capacity.

Moving Beyond Periodic Audits

Traditional audits, spreadsheets, and monthly reports have their place, but they no longer keep up with the speed of Industry 4.0. Manufacturing today operates in a state of continuous motion, where delays in insight directly translate to lost yield and missed opportunities. Kloudspot’s Physical AI eliminates this lag by enabling real-time, adaptive manufacturing intelligence. It bridges the gap between what’s happening and what can happen next, moving operations from reactive to predictive, from static analysis to dynamic foresight.

The result?

- Greater agility in responding to disruptions

- Data‑validated decisions made at the edge

- Sustainable yield growth that compounds through continuous improvement

For manufacturers aiming to redefine efficiency, it’s time to evolve beyond periodic audits and into a world of perpetual intelligence. With Kloudspot’s Physical AI platform, your plant learns, adapts, and thrives.